Maintenance & Reliability forms a part of multi-level and multi-tool approach Total Productive Maintenance.

Maintenance is primarily the act of keeping a property or equipment in good condition by making repairs in timely manner and up-keeping it in the best shape so as to extract the best quality, in time and in full from it.

Reliability, in maintenance management, encompasses everything that machinery interacts with – technology, culture, and design and maintenance strategy

TPM – Total Productive Maintenance is a pillar of Total Lean

Management and a maintenance philosophy aimed at eliminating

production losses due to equipment ill functioning. TPM is about

keeping equipment in a position to produce at maximum capacity,

the expected quality products, with no unscheduled stops. The

JIPM (Japan Institute of Plant Maintenance) definition of TPM is

T = Total, Must involve all employees at all levels of the

organisation

P = Productive, Effective utilization of all resources

M = Maintenance, Keeping the Man-Machine-Material system in

optimum condition

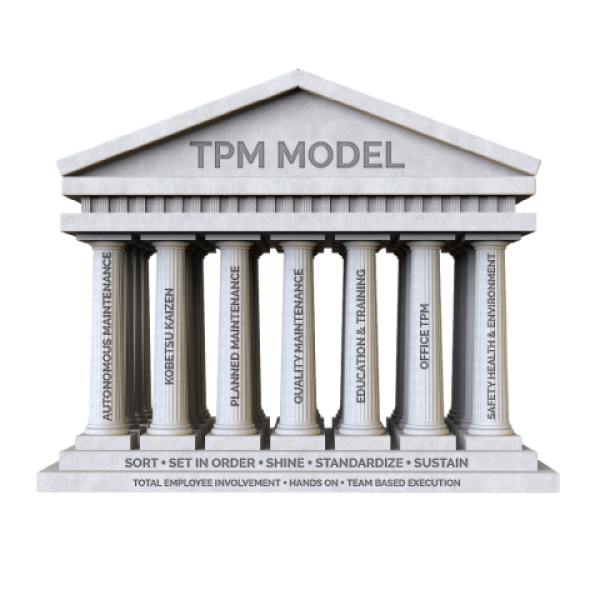

Total productive maintenance has eight pillars that aims at proactively establishing reliability of machines. While focusing on equipment effectiveness, one point that has to be made here is that people are centre of this system and must be continually trained to identify and eliminate waste. It is a system that is based on a clear set of principles and structures and should not be interpreted to be a set of tools or techniques to be applied haphazardly in a view of creating a Lean Environment.

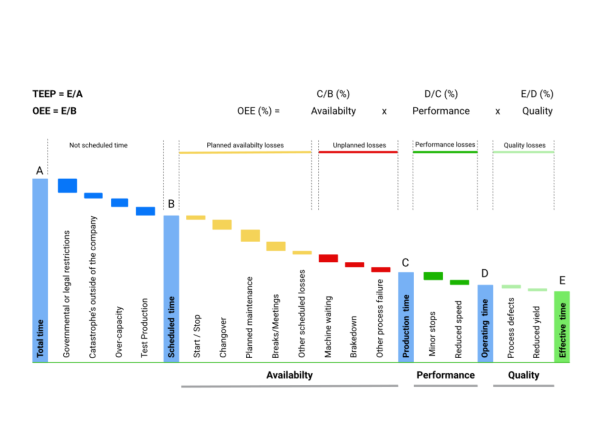

OEE (Overall Equipment Effectiveness) is a metric that identifies the percentage of planned production time that is truly productive. It was developed to support TPM initiatives by accurately tracking progress towards achieving “perfect production”.

Availability factor: It is one of the basic criteria to measure OEE and machine utilization is the most important component of availability.

Performance factor: It is the record of output, which determines whether producing and delivering a product or service as per standards.

Quality factor: It shows the amount of parts/products produced that fully satisfies the pre-set and intended quality standards.

MTBF (Mean Time Between Failures) & MTTR (Mean Time To Repair) are two metrics used for more than 6 decades now, as indicators of the availability of an equipment. These are considered as KPIs from production perspective in world’s best Lean practicing organizations. These metrics gives a brief idea of the overall uptime of your equipment – the productive time it contributed to overall performance.

MTBF (Mean Time Between Failures) – It is the average amount of operating time between consecutive breakdowns for an item of equipment (or plant).

MTBF = Operating Time / Number of Failure or Breakdown Events

MTTR (Mean Time To Repair) – it is the average maintenance time required to keep an item of equipment (or plant) operational.

MTTR = Total Downtime / Number of Failures or Breakdown EventsAs reliable production processes are crucial in a Lean Manufacturing environment, MTBF and MTTR are vital metrics for all lean initiatives. The goal for Lean Improvement s with respect to these KPIs should be:

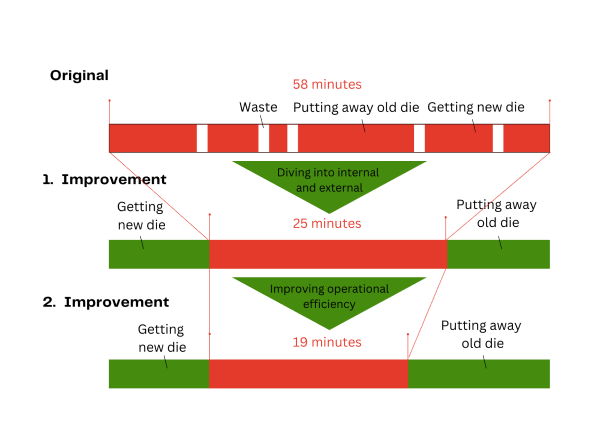

1. MTBF should increase with the improvementsSMED, abbreviation of Single Minute Exchange of Dies (also commonly referred as QCO – Quick Changeover), is a process of reducing changeover (setup) between exchange of setup of a product taken out of production and taking up new product for production.

The key to success is to move as many setup tasks from internal setup to external setup, then reduce the time needed to complete the internal tasks.

The customer won’t pay for something that you haven’t produced. So anytime that is consumed as downtime is a waste, MUDA of waiting to be precise, since the new product is waiting for the machinery to be set-up for it. This downtime is not something that is not foreseen. Instead it is something that is always planned. Hence the time consumed during this changeover shall always be restricted to the minimum value as much as possible.

Reliability, as a concept, is defined as the probability that a component or system will perform a required function for a given time when used under stated operating conditions. To be understood simply, one can say that if an equipment often breaks down unexpectedly, its reliability is very less.

Many organization even in today’s time considers maintenance with an approach of ‘fix it when broken’. This is termed as condition based maintenance. But in a manufacturing environment, where quality of production is considered as the actual output, this traditional concept of maintenance poses many challenges. With time, the maintenance approach has also evolved from that of the traditional one. Reliability centred maintenance is the approach that world class manufacturing organizations have adopted.

Through MTBF, we can know the failure rate of an equipment. This failure rate becomes the basis to calculate the reliability of that equipment.

The formula to calculate reliability for the intended time

interval:

Reliability for time ‘t’, R(t) = e(-λt)

While this formula gives the current scenario of an equipment, one can set targets of controlling failure by deciding the reliability standard to be met in intended time interval. This in turn helps in devising the maintenance strategy for an organization.

For more details about Lean Manufacturing Training & Consulting Email : info@avci-lean.com or Call / Whatsapp : +91 9824009792