Factory Layout & a Lean Plant design is fundamental for building manufacturing excellence, by optimizing space and manpower, reducing costs, and ensuring on-time defect-free deliveries.

A Lean Factory Layout Design is the heart of manufacturing excellence, which ensures smooth material flow, at least cost. Plant Layout Design needs to be reviewed periodically, to remove the Muda in material flow, and reduce the through put time from order to delivery.

Unorganised material flow, increases cost of goods sold, due to excessive material handling, high material movement, more manpower, etc.

A smooth Factory Layout Design, reduces these costs and increases gross profits.

A Lean Plant Facility ensures high-capacity utilization, smooth material flow and creates a Visual Factory.

Plant layout and design, in a way, can be termed as the skeletal system of the entire manufacturing excellence design, which supports other manufacturing excellence tools and concepts.

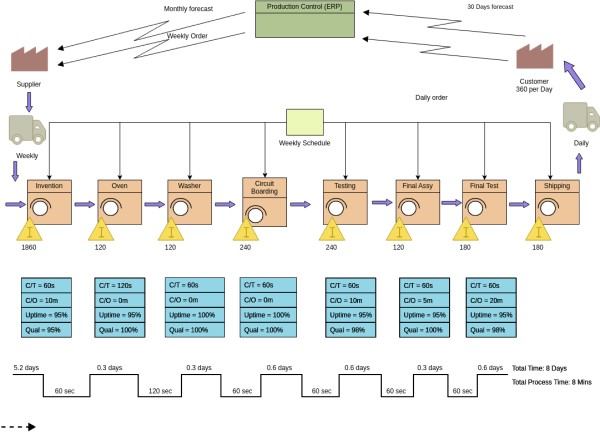

Value-stream mapping, also referred to as "material- and information-flow mapping", is a highly strategic lean manufacturing tool for analysing the present state and designing a future state of the manufacturing processes. A value stream map is a visual tool that displays all critical steps during a process and quantifies easily the time and volume taken at each stage. It should always be the first and last step of designing a Lean Layout.

Although value-stream mapping is usually related to manufacturing, it's also utilized in logistics, supply chain, service-related industries, healthcare, software development, development, and administrative and office processes. Value Stream Mapping helps in improving designing Manufacturing Strategy.

Plant Layout Design is highly essential for smooth material flow and creating an effective and efficient manufacturing plant.

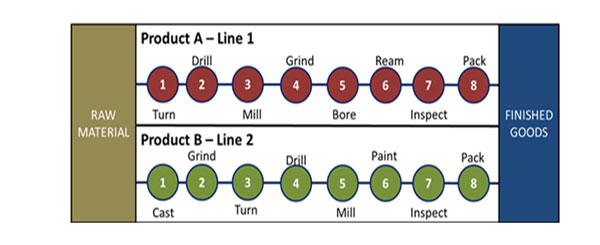

Cellular manufacturing is a manufacturing process that produces families of parts within one line or cell of machines operated within the cell by machinists. Different shapes of manufacturing cells can be created to aid smooth material flow.

Achieving Manufacturing Excellence means to manufacture as per TAKT Time, in small batches or One piece at a time.

A Line Layout means designing the Plant Layout by aligning the processes as per product flow requirement. Line layouts help manufacturing product families requiring the same process sequence and almost similar work standardization.

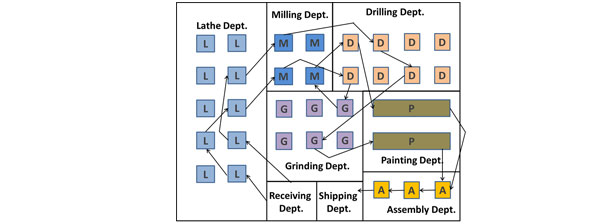

Functional Layouts have machines and equipment performing similar operations in one location. Products with varying cycle times and Takt times require such Function Plant Layouts.

In practice, plants are not usually laid out either in product or process layout form. Generally, a mix of the 2 basic layouts is used to derive the benefits of both systems of layout. The combination is suitable to most businesses where variants are to be managed for a similar product family.

It is also called stationary layout. In this type of layout, a product remains in one place owing to its size and men, materials, and machines are brought to it. Shipbuilding, air-craft manufacturing, heavy construction of dams, wagon building, bridges, buildings, etc. are typical examples of such layouts.

ADDVALUE are one of the leading Lean Consultants in India, for Plant Layout, Shopfloor Design and Factory Vastu Layout Design.

For more details about Lean Manufacturing Training & Consulting Email : info@avci-lean.com or Call / Whatsapp : +91 9824009792